According to the knowledge of Labor Newspaper reporter, the steel factory complex of Xuan Thien Group in Nghia Hung District (Nam Dinh) was approved by Nam Dinh Provincial People’s Committee in Decision No. 2186/QD-UBND and Decision No. 2188/QD-UBND on 9.10.2021 with a total investment of 69,000 billion VND, total capacity of 7.2 million tons/year.

On the afternoon of March 22, Mr. Tran Anh Dung – Vice Chairman of Nam Dinh Provincial People’s Committee signed decisions on adjusting the investment policy for the above steel factory complex of Xuan Thien Group. Accordingly, the People’s Committee of Nam Dinh province has approved, adjusted to increase the total investment from VND 69,000 billion to VND 98,000 billion, with a capacity of 9.5 million tons/year. But the total land area used for the project has not changed. This is considered one of the “crisis” projects in Nam Dinh province, contributing significantly to the orientation of the province’s clean industry development as well as generating budget revenues and creating jobs for local workers.

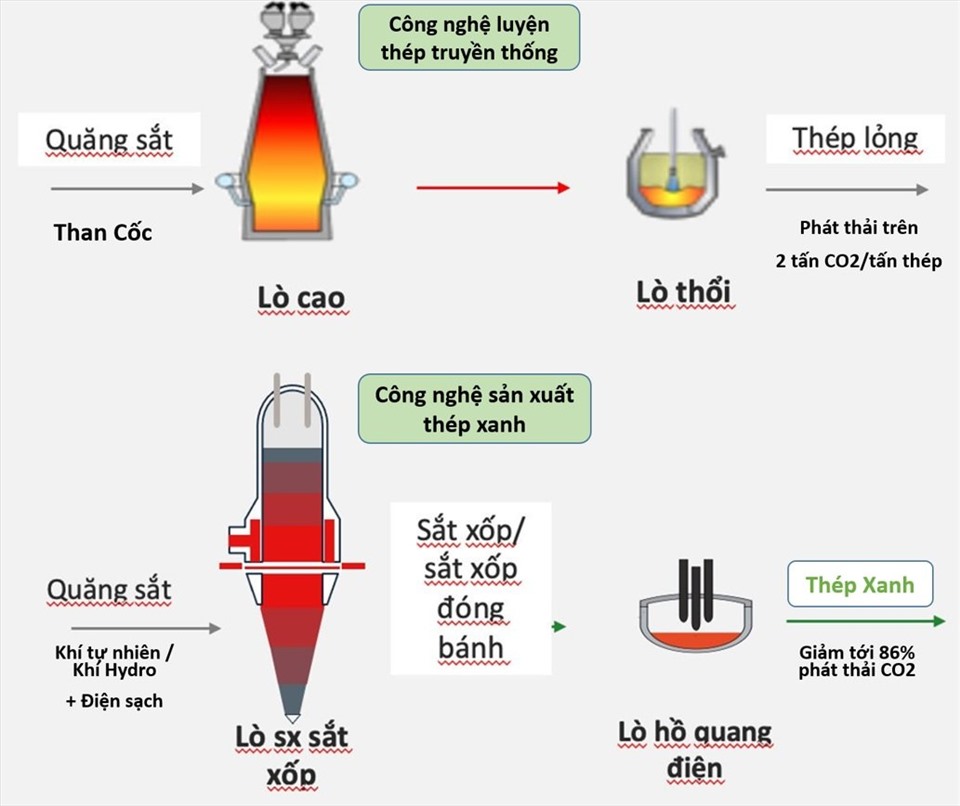

“The adjustments are aimed at selecting steel production technology that is more suitable to the increasing requirements of environmental protection. To reduce CO2 emissions into the environment, investors have changed the technology, no longer using coke but switching to gas and hydrogen to revert steel, ”said Vice Chairman of Nam Dinh Provincial People’s Committee Tran Anh Dung.

Xuan Thien Group is known to be the leading company in renewable energy production in Vietnam today, including hydropower, solar power and wind power.

Talking to Labor Newspaper reporter, Mr. Nguyen Huy Hoang – General Director of Xuan Thien Nam Dinh Joint Stock Company said: “in the past, with the use of coke to revert steel, each ton of steel produced will emit 2.0-2.5 tons of CO2 into the environment. By switching to technology that uses gas and hydrogen to revert steel, it is possible to reduce CO2 emissions by up to 86% compared to the old method.

The difference between traditional steelmaking technology and green steelmaking technology. Photo: NT

“Although we have to spend tens of trillion VND more to change the technology, this is essential, while ensuring environmental factors and also the conditions for our steel to be exported to difficult markets like Europe – which currently encourages the production of clean raw materials and energy. For every tonne of green steel product today, without the support of the Government on CO2 emission reduction policy, there would be a higher production cost than conventional steel of about 250EUR/tonne of product. According to the consultants of leading European agencies, currently European countries are having policies to encourage emission reduction of about 75-100EUR/ton of CO2, so it has been possible to balance the cost between the use of green steel and conventional steel. With the Vietnamese market, we are confident that the Government will have similar mechanisms to encourage green steel production, protect the environment.” – Mr. Hoang added.

Suoce: Labor Newspaper